Successful Production! ALBA Partners with Meyer Optoelectronic to Create Top-Grade Food-Grade rPET!

In the first quarter of 2024, ALBA Longyi New Materials (Jiangxi) Co., Ltd. successfully produced the first batch of food-grade rPET. The project is located in Yingtan, Jiangxi Province, and is the first plastic recycling project in mainland China for ALBA, a global leader in resource regeneration and circular economy. The factory can safely, greenly, and environmentally transform 2 billion discarded beverage bottles into recycled materials suitable for food grade each year, achieving a closed-loop recycling of waste plastics.

Established in 1968, ALBA, headquartered in Berlin, Germany, is a Fortune 500 company dedicated to providing environmental solutions, focusing on discovering the potential value in waste. Over 50 years, ALBA has been seeking systematic solutions to reduce waste generation and achieve the recycling of waste materials, aiming to build a zero-waste world. Since 2017, ALBA has cooperated with Meyer Optoelectronic, a leading company in the waste plastic sorting field.

ALBA Longyi New Materials Processing Production Line

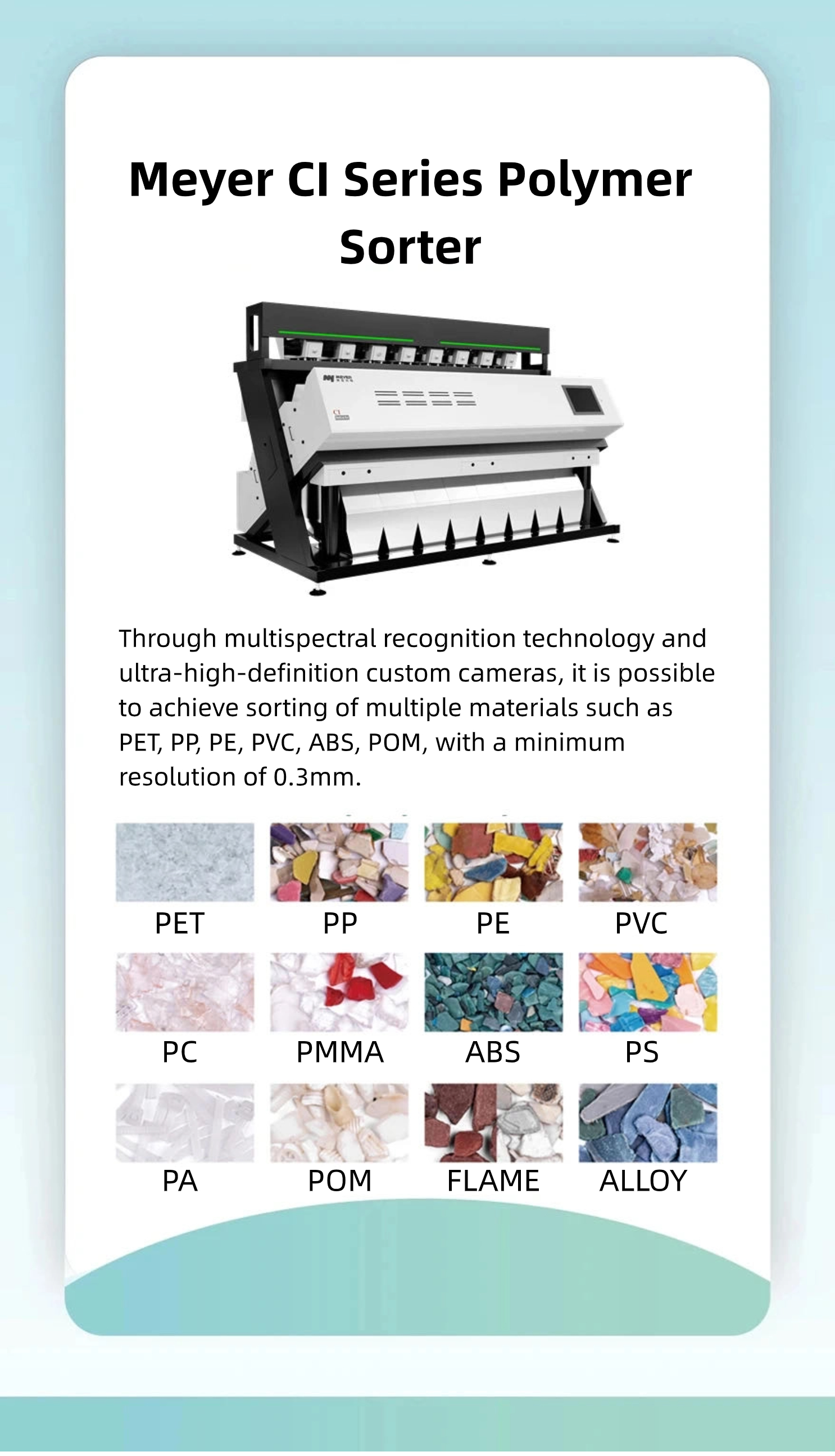

Food-grade rPET has higher quality and safety compared to ordinary rPET, mainly used for overseas exports. The raw materials need to undergo strict screening and cleaning, which places high standard requirement on bottle flakes sorting, especially in the polymer sorting process. ALBA uses Meyer CI polymer sorting machine in this processing stage, significantly improving the purity of rPET products.

Meyer's new CI series multispectral plastic polymer sorting machine uses multispectral identification technology, providing polymer or color sorting solutions, can detect and remove various non-PET materials in bottle flakes, with a minimum resolution of 0.3mm, and effectively identify various colors and aluminum flakes, supporting secondary and tertiary re-sorting. The product is based on engineering design and intelligent manufacturing to ensure highly stable and reliable machine operation.

Meyer Optoelectronic Recycling Customer Cases

Meyer's recycling products have been applied to numerous waste plastic processing production lines in more than 50 countries and regions worldwide, sorting out tens of millions of tons of high-purity recycled plastics for the industry, earning widespread praise from customers at home and abroad. Meyer Optoelectronic will continue to create value for the recycling resource industry and make greater contributions to industry development.

- Previous:Nut intelligent manufacturing, excellence as king!Meyer released three major innovations at 2024 Food Exhibition for China Nuts and Dried Fruits!

- Next:Congratulations to Meyer UHD Deep Learning Belt Color Sorter for winning the "Top 10 Innovative Agricultural Machinery Products" in Anhui Province!