CHINAPLAS丨Too Many Customers... Meyer Whole Scene Plastic Sorting Solutions Recognised by Global Customers!

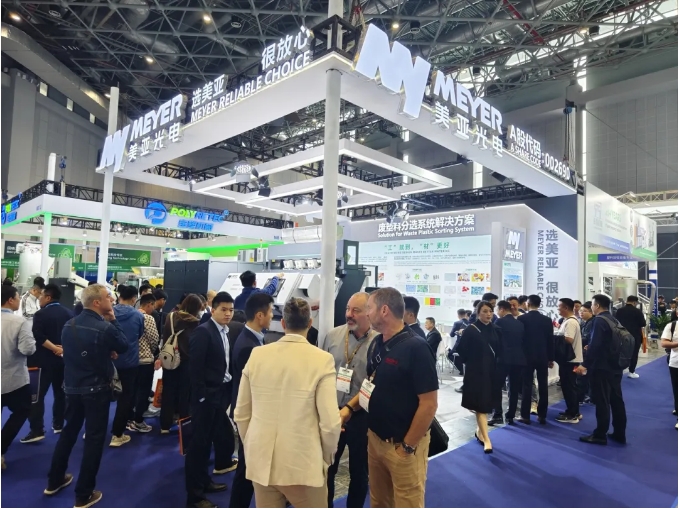

2024 International Exhibition on Plastics and Rubber(CHINAPLAS) was successfully held in Shanghai, China from 23 to 26 April. The unprecedented scale of this exhibition attracted 4,420 exhibitors and more than 300,000 visitors. Meyer showed whole scene plastic sorting solutions on-site, received the attention and praise of many customers at home and abroad.

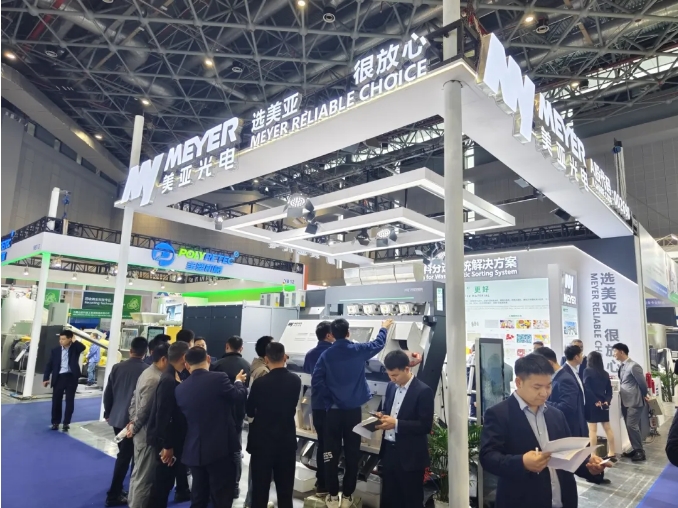

During the 4-day exhibition, Meyer's booth was very popular with customers!

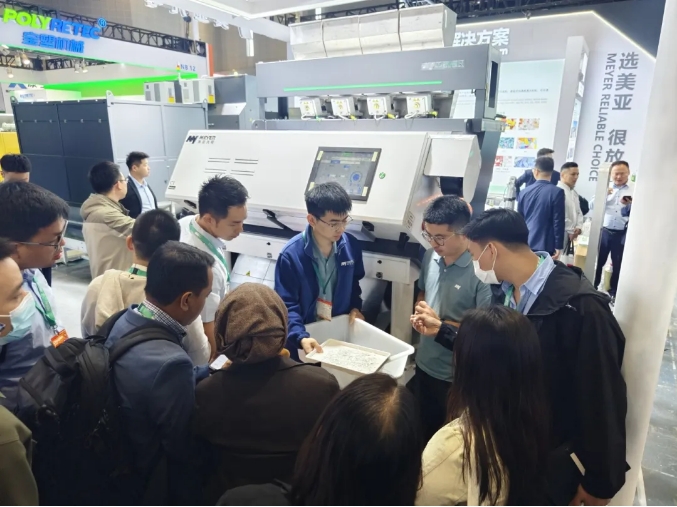

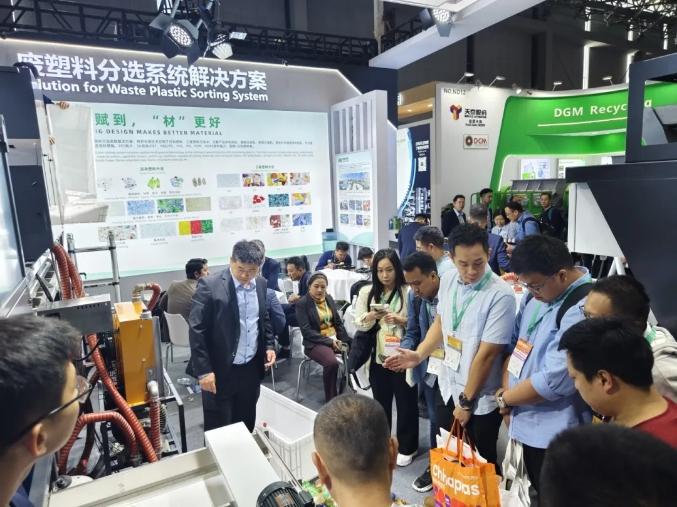

Customers looked closely at Meyer's whole scene plastics sorting solutions

Meyer was praised by customers

Why are Meyer's whole scene plastic sorting solutions so popular? In response to the industry's increasingly prominent demand for polymer sorting of plastics, Meyer brought two new engineering products this exhibition, incorporating deep learning and multi-spectral recognition technology, which are widely used in the field of daily and engineering plastics to fully satisfy the needs of customers for color and polymer sorting of whole bottles, bottle flakes and miscellaneous materials.

Highlight 1: Engineering

Meyer as early as 2015 to vigorously promote the "engineering" innovation, from the source of design to strictly promote the "standardization, modularization, intelligence", like building blocks, individual systems or functional components of equipment with a certain scale is combined into a whole with distinctive modules and strong systematicity according to certain specifications; at the same time, the traditional manufacturing mode is changed to achieve standardized and intelligent manufacturing from the production of parts and components to the assembly of the whole machine, which guarantees the quality of the products in an all-round way.

Meyer color sorter assembly line

Highlight 2: Polymer Sorting

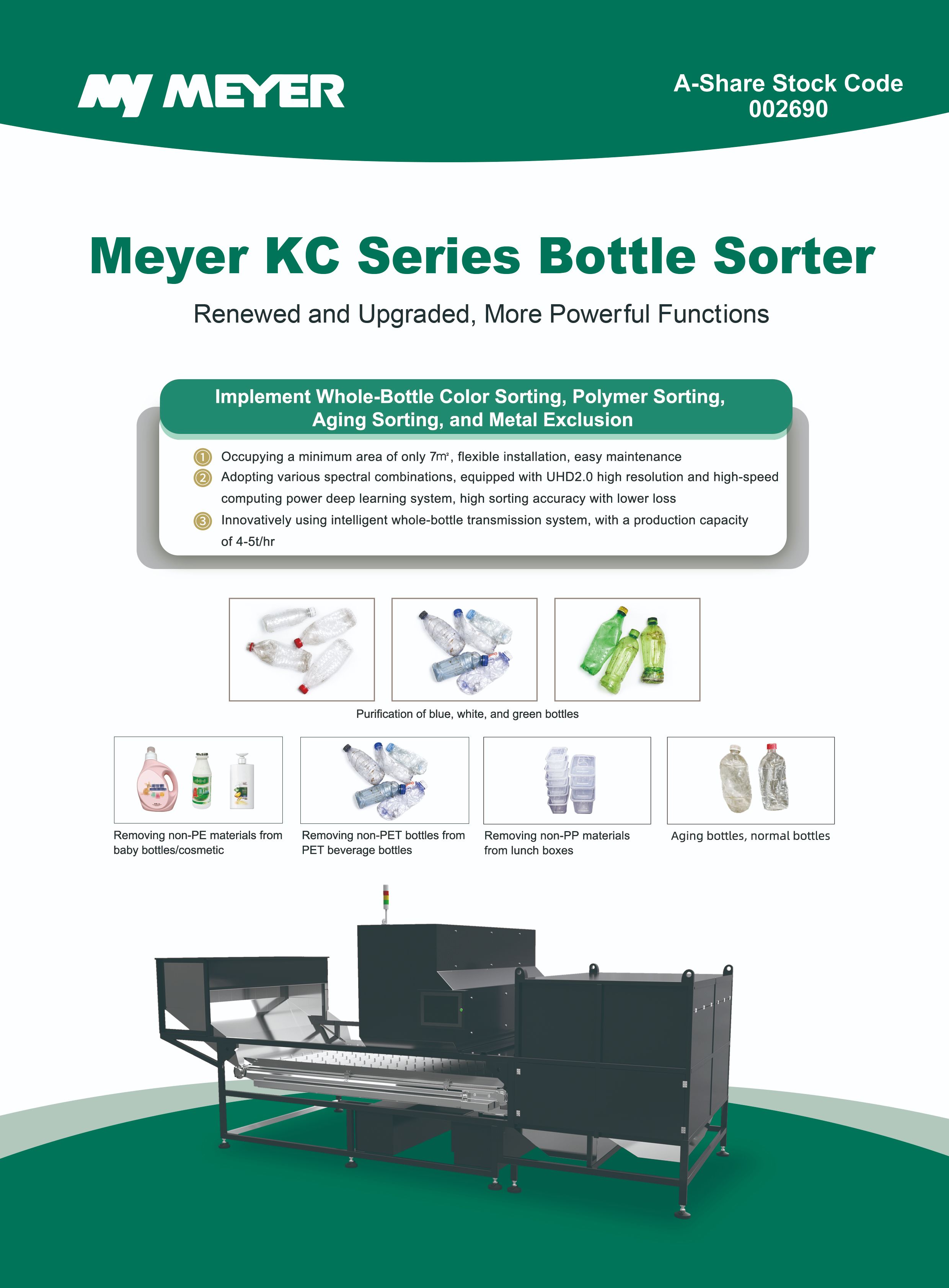

Meyer whole bottle sorter KC can effectively carry out whole bottle color sorting, multi-polymer and aging bottle sorting: eliminate non-PET bottles from PET bottles, eliminate non-PE materials from milk bottles/daily necessities, eliminate non-PP materials from lunch boxes, eliminate aging bottles from whole bottles, as well as white/blue/white bottles purification, etc. It can help customers to reduce the cost of labor, and contribute to the expansion of production and efficiency and the development of transformation; meanwhile, it can help customers to purify the raw materials of whole bottles, reduce the pressure of back-end sorting, and improve the quality of final products.

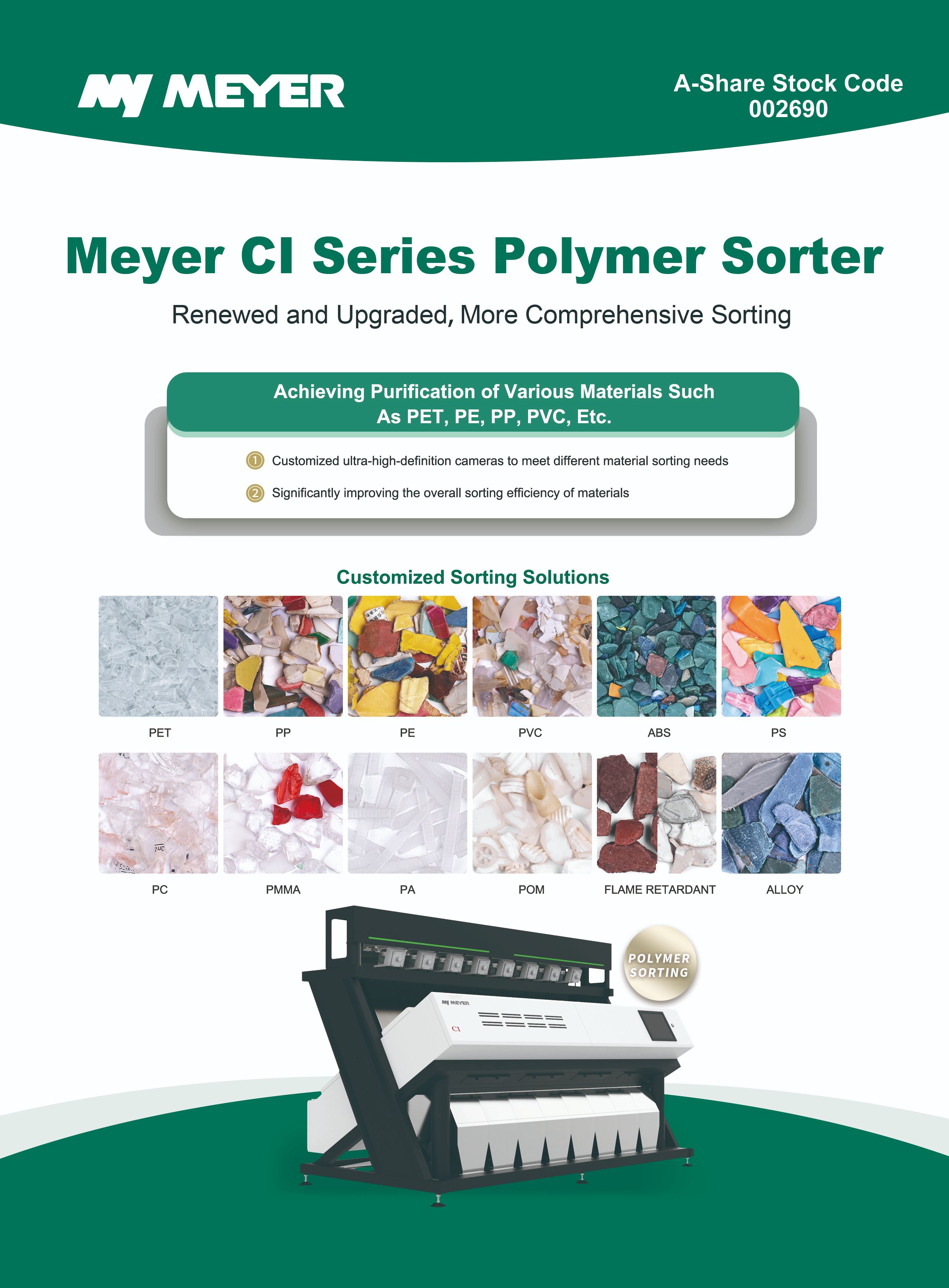

Meyer polymer sorter CI, using multi-spectral recognition technology and ultra-high definition custom camera, provides polymer sorting or polymer and color sorting solutions. It can detect and sort out different materials such as PET, PP/PE, POM, ABS, PVC and other plastics with a minimum resolution of 0.3mm, and it can also effectively identify all kinds of different colors and aluminum flakes. It makes previously unmanageable waste and miscellaneous materials more valuable, helping customers to turn waste into treasure and increase revenue.

As a national key high-tech enterprise that has been ploughing into the recycling industry for 16 years, Meyer has always been working side by side with upstream and downstream partners in the industry. In the future, Meyer will carry forward the core culture of "integrity, realism and innovation", strictly practice the core value of "pursue quality, serve customers", resolutely carry out the medium-and long-term development strategy, continuously improve our core competitiveness, focus on performance, reliability and other key indicators, strive to make our products the best, and continue to enhance the customer experience to firmly establish the brand image of "Meyer, Reliable Choice".